典藏品介紹

典藏品介紹

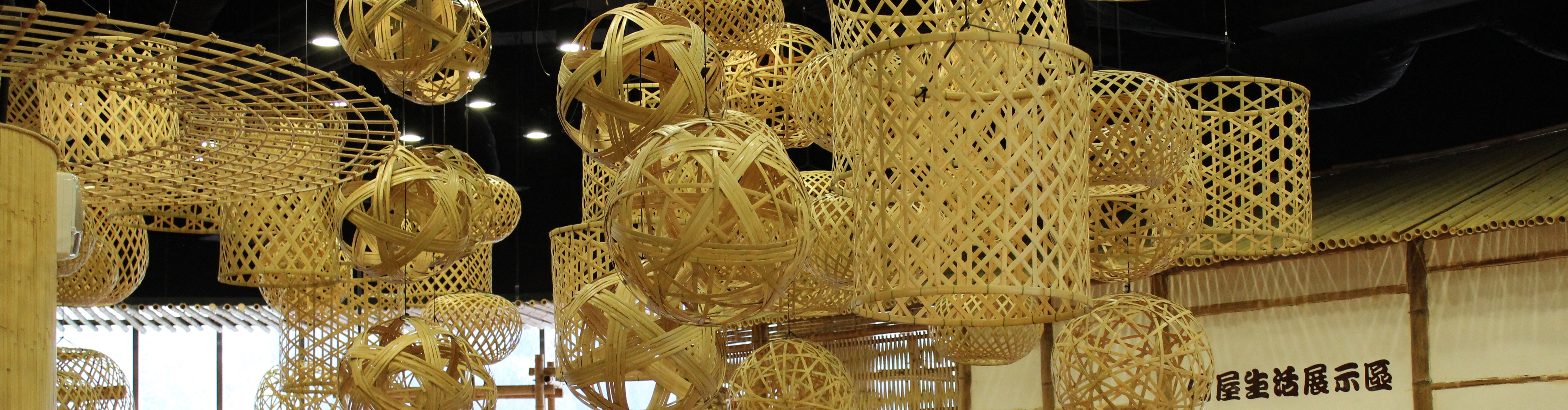

竹製傢俱

| 作品名稱 | 竹製傢俱 |

| 作品尺寸 | 茶几:長122cm 、寬62cm 、高62cm 椅子:長66cm 、寬68cm 、高103cm |

| 語音 |

竹製傢俱中文語音 竹製傢俱英文語音 |

簡介

| 竹製傢俱的加工方式原則上可分為兩種,一種是保留中空管狀的特性,所做成的傢俱,另一種是用竹片積層膠合後,所做成的積層竹傢俱,前者的技法所做成的飯桌、菜櫥、竹床、乳母椅和各種倚頭仔等,在民國70年代以前,幾乎是家家戶戶生活上的必須品,而積層竹相關產品的誕生,則約在民國70年代以後,由於膠合劑、高週波、高溫高壓著色、CNC自動車床的結合應用,產品才陸續穩定發展,直到民國90年代以後,各種積層竹產品,如雨後春筍般應市,從原始開發之007手提包到泡茶盤、手飾盒、桌椅、竹地板等,產品琳瑯滿目,不下幾百種。由於孟宗竹片經過膠合後,如同實心的木材,所以能規格化、機械化的大量生產。也因竹材的輪伐期短,再生性強,深具環保特質,所以臺灣竹製產品,近年來也深受歐美國家極度的讚賞與推崇。 此組膠合竹桌椅的加工流程為:孟宗竹裁切→撞成竹片→竹片內外刨平→高溫高壓著色→膠合→材料裁切→圖紋刻劃→組合→砂磨→細部修飾→塗裝。 The processing methods for bamboo furniture can be divided into two types; one retains the hollow character, while the other glues layers of bamboo together. Furniture made by the former technique such as dining tables, cupboards, beds, nursing chairs, and various pillows were household necessities before the 1980s. The birth of layered bamboo occurred after the 80s; the combined application of glue, high frequency rays, high heat/pressure color treatment, CNC automatic machinery allowing steady development of the products. After the year 2000, various layered bamboo products filled the market, including traditional briefcases to tea trays, jewelry boxes, tables and chairs, flooring. There are more than hundreds of the varieties of products. After gluing, moso bamboo becomes as solid as wood and therefore can be standardized and mass produced. The harvest period of bamboo is short. It also has strong regenerative abilities and is environmental friendly. Therefore, bamboo products from Taiwan have been well received in Europe and America. |

附件

竹製傢俱中文語音.mp3

竹製傢俱英文語音.mp3